- Home

- Poly Tetra Fluoro Ethylene Uses

Top 5 Poly Tetra Fluoro Ethylene Uses | Leading Manufacturer for OEM Supply from China

Foosin Medical Supplies Inc., Ltd. is a well-known manufacturer of high-quality medical products, with FDA approval. Our latest product, Poly Tetra Fluoro Ethylene, is a versatile material with numerous uses in the medical industry. Also known as PTFE, it is a synthetic fluoropolymer of tetrafluoroethylene that is hydrophobic, electrically non-conductive, and chemically inert.

PTFE has excellent resistance to high temperatures and is commonly used in the manufacturing of catheters, surgical instruments, and other medical devices. It is also used as a coating on medical wires and cables to improve their electrical insulation and performance.

As an OEM supplier, Foosin Medical Supplies Inc., Ltd. has years of experience in producing the highest quality medical products for our customers. We take pride in our commitment to providing safe, reliable, and innovative solutions for the ever-evolving medical industry. Contact us today to learn more about our PTFE products and how we can meet your medical needs.

Foosin Medical Suppues Inc., Ltd.

Company News

Related News

The most complete varieties and certificates Surgical Sutures brand in China

As a factory, we offer the most complete varieties and certified Surgical Sutures brand in China. Trust us for high-quality sutures that meet your medical needs. #surgicalsutures #medicalsupplies #madeinchina

Polyvinyl chloride resin(PVC Resin)

At our PVC Resin factory, we produce top-quality raw materials for various applications. Trust us to deliver consistency and reliability with every order. Get in touch today! #PVCResin #Factory #QualityMaterials

Sterile Monofilament Non-Absoroable Sutures Nylon Sutures With or Without Needle WEGO-Nylon

WEGO-Nylon provides high-quality sterile monofilament non-absorbable nylon sutures with or without needles. As a factory, we guarantee reliable and efficient service with a focus on customer satisfaction.

WEGO Hydrogel Sheet Dressing

WEGO Hydrogel Sheet Dressing is a revolutionary wound care solution that promotes healing and reduces discomfort. As a trusted factory, we ensure quality standards are met for every product. Trust us for innovative and effective wound care solutions.

Sterile Monofilament Absoroable Polydioxanone Sutures With or Without Needle WEGO-PDO

Our factory produces high-quality sterile monofilament absorbable polydioxanone sutures with or without needles under the WEGO-PDO brand. Trust us for reliable and durable surgical sutures.

Veterinary Medical Devices

Looking for high-quality veterinary medical devices? Look no further than our factory! We offer a wide range of products to meet all your needs. Order today.

Non-Sterile Monofilament Absoroable Polydioxanone Sutures Thread

Looking for high-quality non-sterile monofilament absorbable polydioxanone sutures thread? Look no further than our factory! We offer top-notch products made with the latest technology to ensure superior performance and results. Order today!

Acne Cover

Looking for reliable and affordable acne cover products? Our factory has got you covered! Get high-quality, effective products that will help you achieve clear, beautiful skin. Shop now! #AcneCover #FacialSolutions #SkinCare.

WEGO Surgical Needle - part 2

Looking for high-quality surgical needles? WEGO Surgical Needle - part 2 is your best bet! We are a factory that produces top-notch surgical needles that meet international standards. Order now!

WEGO MEDICAL GRAND PVC COMPOUND

We are a factory producing high-quality WEGO MEDICAL GRAND PVC COMPOUND for medical devices. Our compound offers superior performance and durability. Contact us today!

Absorbable Surgical Catgut (Plain or Chromic) Suture with or without needle

Looking for absorbable surgical catgut suture? Look no further than our factory for plain or chromic options with or without needles. Trust our quality products for your medical needs.

Sterile Monofilament Non-Absoroable Polyvinylidene fluoride Sutures With or Without Needle WEGO-PVDF

Looking for high-quality PVDF sutures? Look no further than WEGO-PVDF. As a leading factory, we offer both sterile monofilament non-absorbable sutures with or without needles. Visit us today!

Sterile Non-Absoroable Polytetrafluoroethylene Sutures With Or Without Needle Wego-PTFE

Looking for top-quality PTFE sutures? Look no further than Wego-PTFE! Our factory produces sterile non-absorbable PTFE sutures with or without needles for superior wound closure.

Supramid Nylon Cassette Sutures for veterinary

We are a leading factory of durable and high-quality Supramid Nylon Cassette Sutures for veterinary use. Trust us for strong, reliable and affordable sutures. Order now!

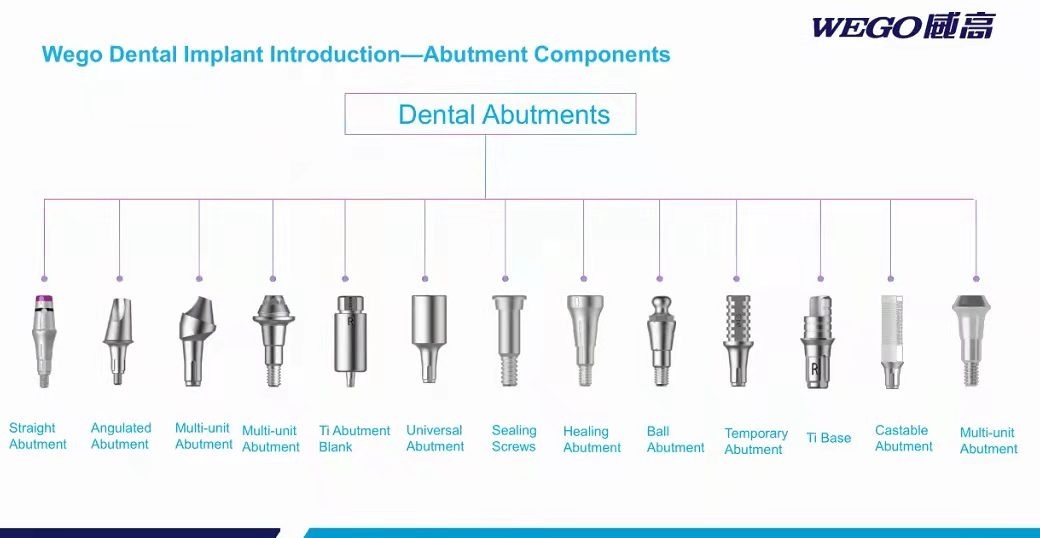

Implant Abutment

Discover high-quality implant abutment products from our factory. Our expert craftsmen produce top-notch abutments at cost-effective prices. Order now!

- Top 5 Uses of Poly Tetra Fluoro Ethylene: A Comprehensive Guide for Manufacturers

- Reviews

- Related Videos

Poly Tetra Fluoro Ethylene (PTFE) is a synthetic material commonly used in various applications due to its unique properties. Its remarkable non-stick and high-temperature resistance features make it an ideal material for use in diverse industries, such as food processing, aerospace, electrical, automotive, medical, and many others. One of the critical uses of PTFE is in the production of non-stick cookware, bakeware, and kitchen accessories. Its non-stick properties help in cooking, baking, and cleaning, making it a favorite in most kitchens. In the automotive industry, PTFE is often used to make fuel hoses, brake lines, and gaskets due to its high-temperature resistance. It's also commonly used in the aerospace industry to fabricate parts for aircraft engines, sealing rings, and insulation. In the electrical industry, PTFE is used to coat wires and cables, insulation materials, and capacitor films. It offers excellent dielectric properties, making it ideal for electronic and telecommunication applications. In the medical field, PTFE is used to make surgical implants, catheters, and other medical devices due to its biocompatibility. In conclusion, PTFE is a versatile material with countless applications in various fields, primarily due to its non-stick and high-temperature resistance properties. Whatever industry you are in, PTFE can be used in numerous ways to meet your specific needs, making it an excellent investment for businesses that require its unique properties.

I recently purchased a product made of Poly Tetra Fluoro Ethylene and I am extremely impressed with its durability and versatility. This material is commonly known as PTFE and is used in a wide range of applications due to its unique properties. It is non-reactive, heat resistant, and has a low friction coefficient, making it ideal for use in cookware, industrial parts, and even medical implants. My product has held up well to constant use and still looks brand new. I highly recommend investing in PTFE products for their quality and longevity.

Poly Tetra Fluoro Ethylene or PTFE is a versatile material with numerous applications. One of its primary uses is in the manufacturing of non-stick coatings for cookware, which I recently tried and was quite impressed with. The coating ensures that food doesn't stick to the pan, making the cooking process much easier and hassle-free. Additionally, PTFE is also used in the medical industry for the manufacturing of implantable devices and as a sealant in the automotive industry. Its high resistance to heat, chemicals, and UV radiation make it an ideal material for several industries. Overall, I am highly impressed with the capabilities of PTFE and look forward to exploring more of its applications.

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours